Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

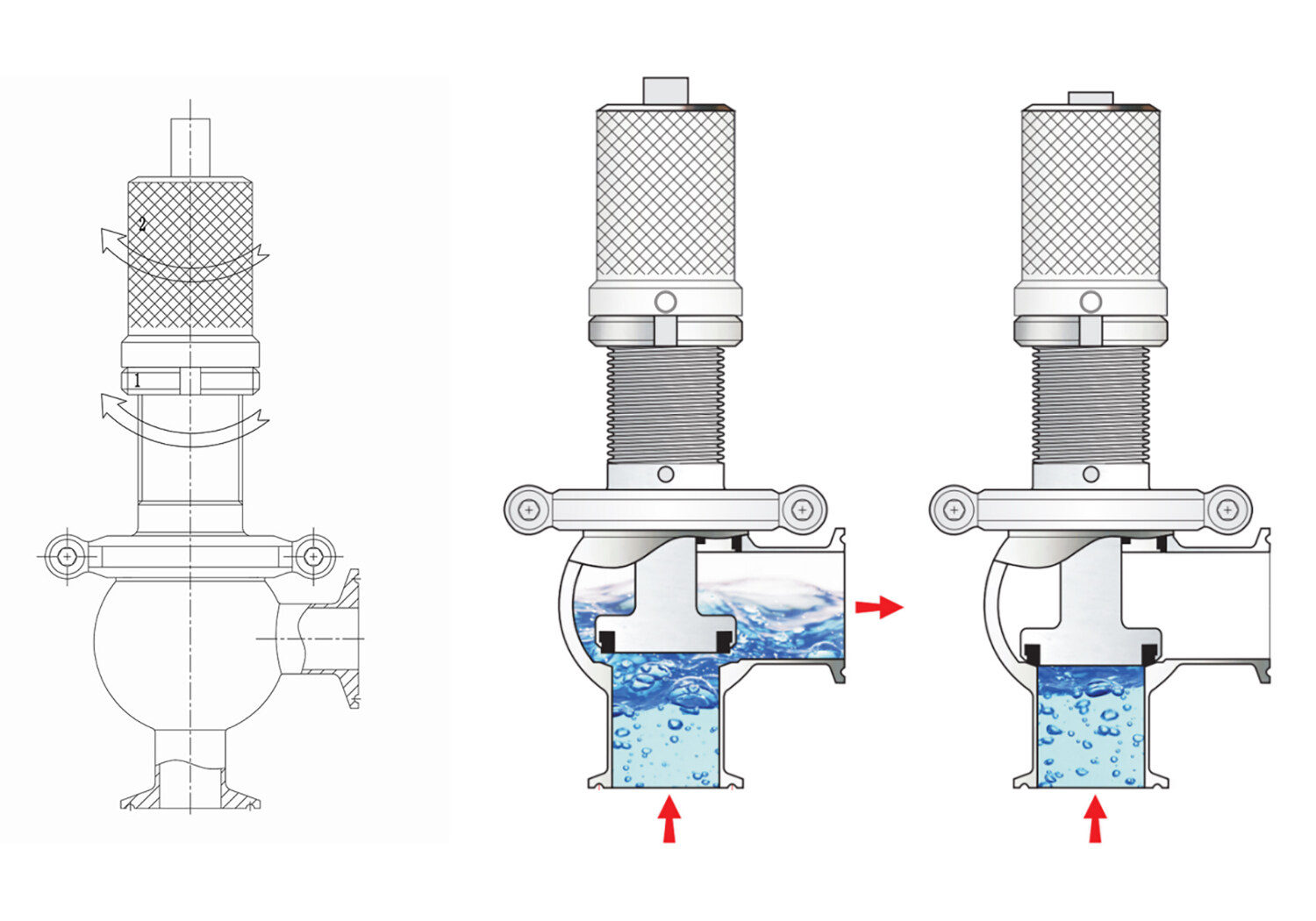

Constructed with high-quality materials and designed for durability, the Sanitary TC Safety Valve offers reliable and consistent performance even in challenging operating conditions. Its robust design and reliable operation give you peace of mind, knowing that your system is protected.

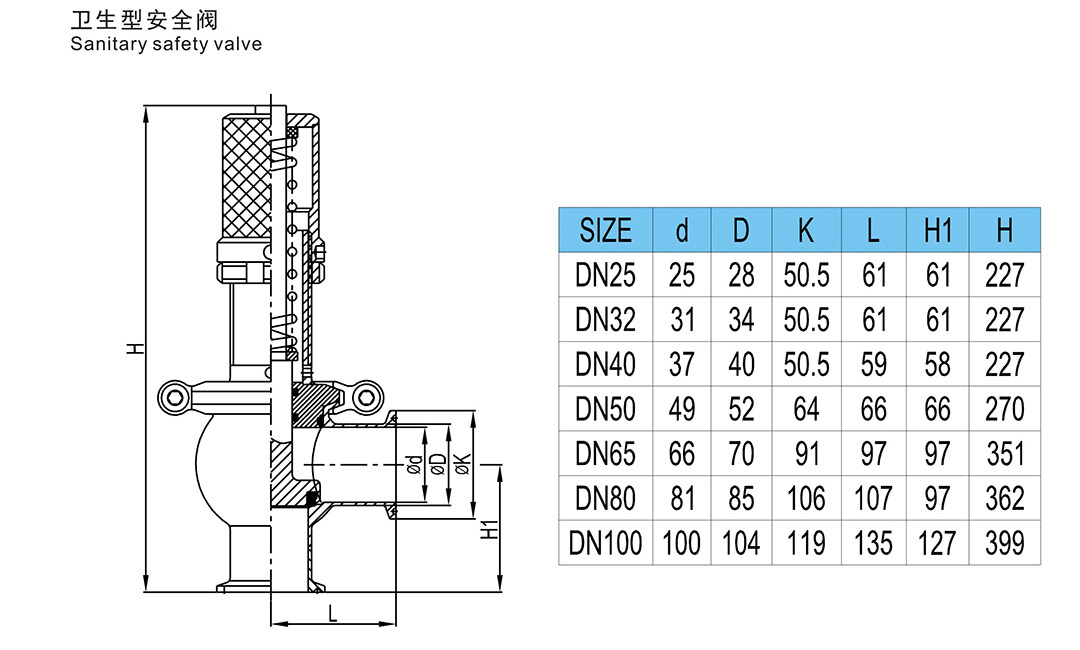

Product parameter

| Standard | SMS,DIN,3A | |

| Material Contact Parts | SS304/SS316L(1.4301/1.4404) | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Size | 1” to 4”,DN25 to DN100 | |

| Connection | Butt-weld,Tri-clamp,Male Thread,Female-Male Threaded,Union,Weld-Thread,Flange | |

| Seal Material | Silicone,EPDM,FKM,Buna,PTFE.All seals material comply with FDA21CFR117.2600 | |

| Media | Liquid,Gas | |

| Power Option | Manual,Pneumatic,Manual-Pneumatic | |

| Working Pressure | ≤12bar(174psi) | |

| Supply Pressure for Air Actuator | 5~8(72.52psi~116psi) | |

| External Surface Treatment | Ra32~64uin(0.8~1.6um) | |

| Internal Surface Treatment | Ra16~32uin(0.4~0.8um) | |

Choose the Sanitary TC Safety Valve for its high-pressure capacity, sanitary construction, quick response time, adjustable blowdown, easy installation, enhanced system safety, regulatory compliance, cost savings, versatile application range, easy maintenance, personnel protection, process efficiency, and reliable performance.

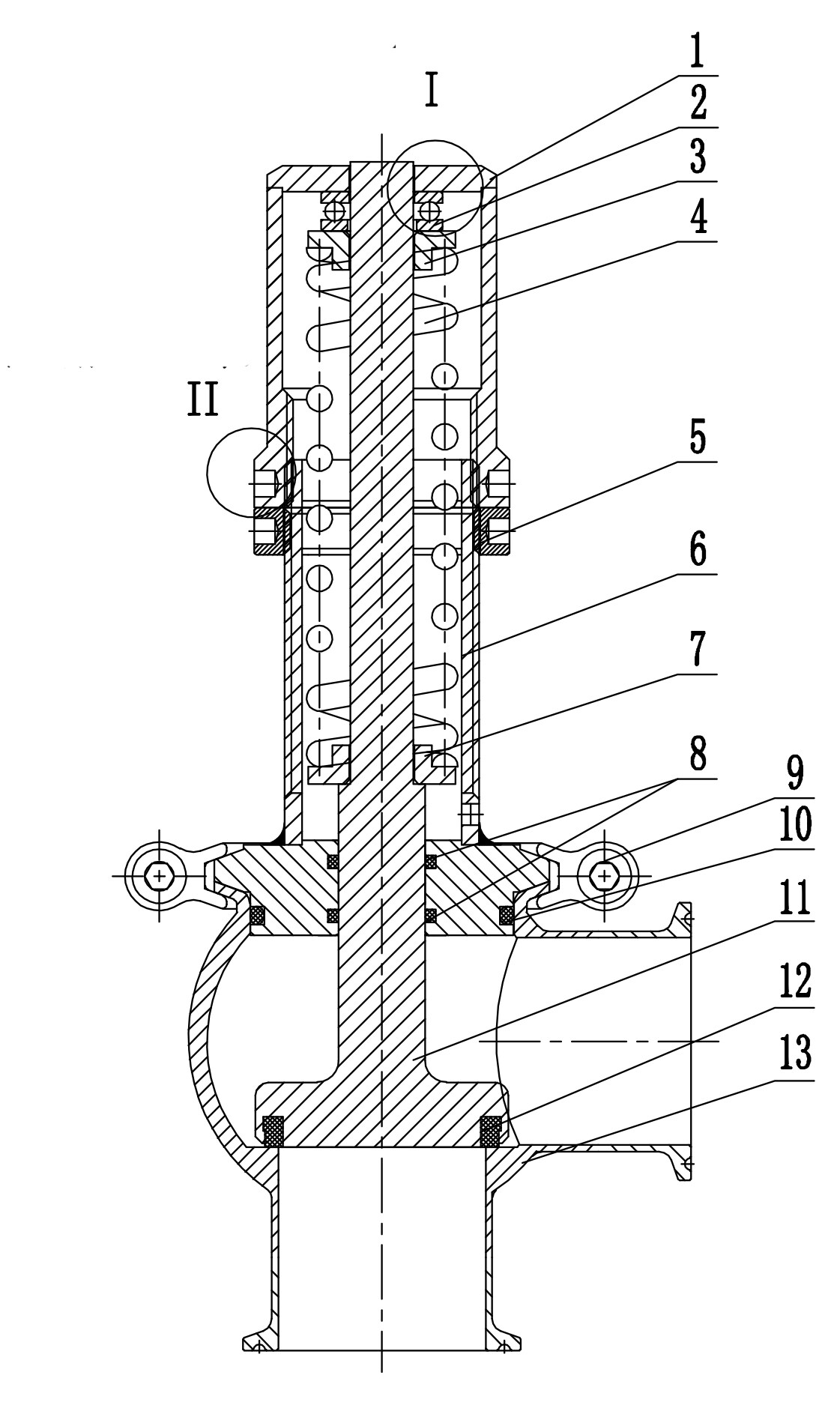

Product drawing

Product Features

Application scenario

Product Advantages

1.System Protection: The sanitary safety valve protects the system from overpressure, preventing potential damage to equipment, pipelines, and other components. By releasing excess pressure, it helps maintain the integrity of your system and prolong the lifespan of your equipment.

2.Personnel Safety: By releasing excess pressure, the valve ensures the safety of personnel by preventing potential accidents or injuries caused by pressure buildup. It acts as a crucial safety measure, protecting your workforce from potential harm in high-pressure environments.

3.Process Integrity: The valve plays a vital role in maintaining the integrity of the process. By preventing pressure-related issues such as leaks, bursts, or system failures, it ensures the smooth operation of your process, minimizing disruptions and maintaining product quality.